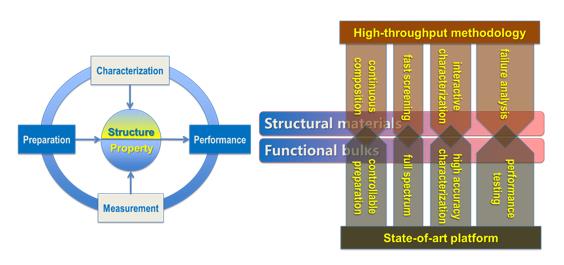

COMPACT(Center of Materials Processing and Characterization Technologies) is an experimental infrastructure to develop integrated technologies on bulk materials preparation, property and structural characterization as well as performance testing by involving MGI methodologies, which are connected with each other to form a unbroken research chain. These are built onto the state-of-art instrumental platforms, hence enabling both the efficient and high accuracy mapping for the composition-structure-property relationship that are ready to serve for the performance and failure testing.

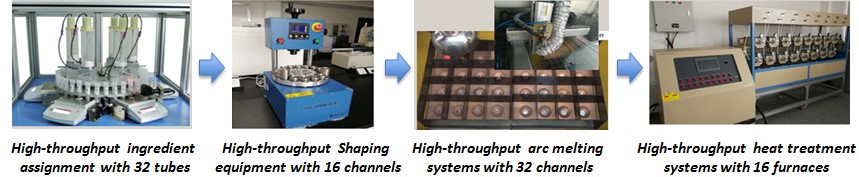

High-throughput methodology and equipment:

1. High-throughput Integration preparation systems for Special alloys

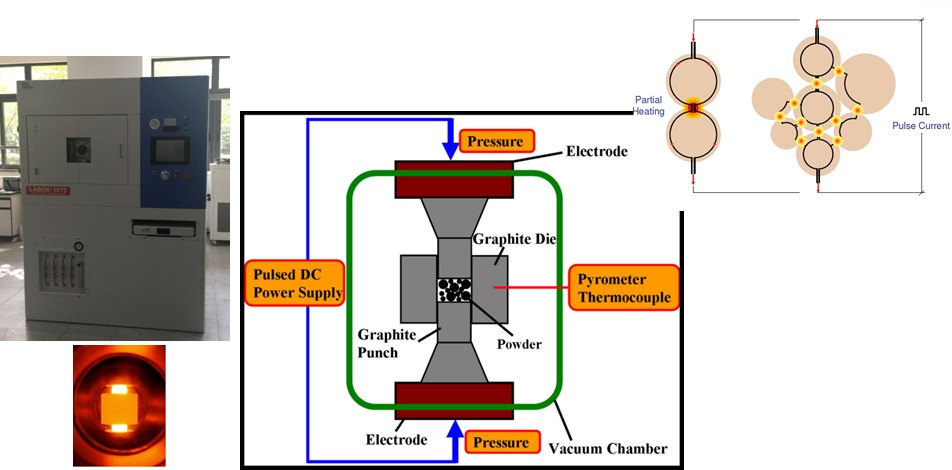

2. Spark Plasma Sintering (SPS) technology

The key of spark plasma sintering (SPS) is that the pulsed DC current directly passes through powder compact, which can cause partial melting of the powders or even plasma. The powders can be sintered into bulks close to theoretical density in several minutes.

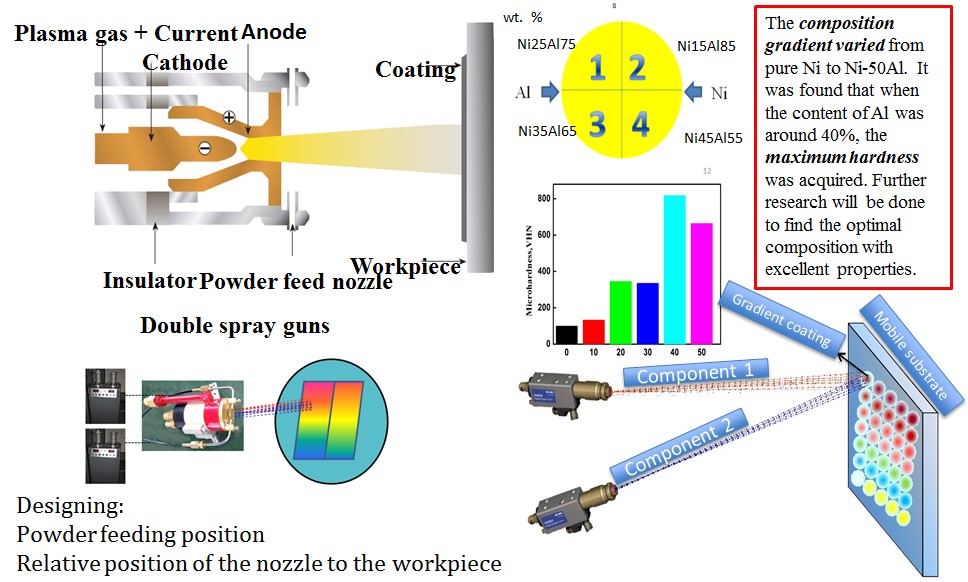

3. Synthesis of thick film materials via plasma spray

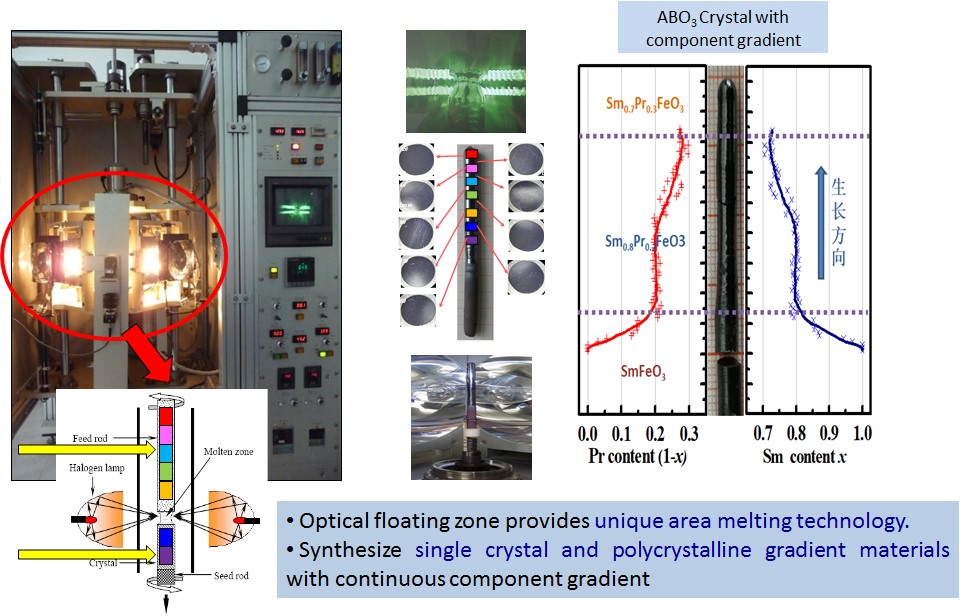

4. Optical floating zone for functional graded crystal materials

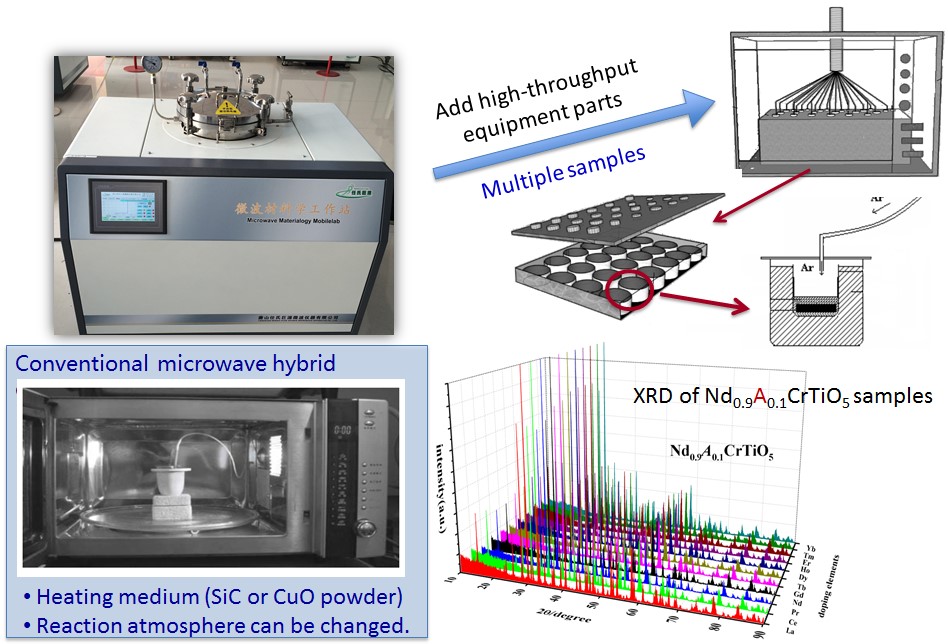

5. Synthesis of powder and bulk materials via microwave hybrid heating

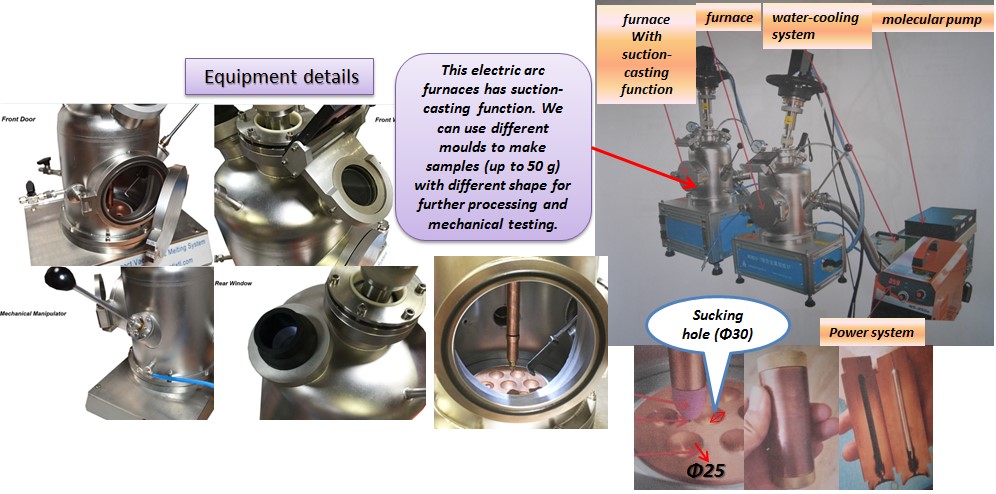

6. Manual Dual Arc Smelting System (DASS)

This system has two manual vacuum electric arc furnaces with and without suction-casting function, both of which could turn over alloy ingot and remelt samples multiple times in vacuum. It is an ideal equipment to produce the refractory metal and metal carbides specimen.

This system is a complement for Multi-station Arc Smelting System (MASS). After high-throughput screening with MASS, the potential candidate alloy can be prepared using DASS to produce a sample in a larger size with a desired shape for further processing or mechanical measurement.

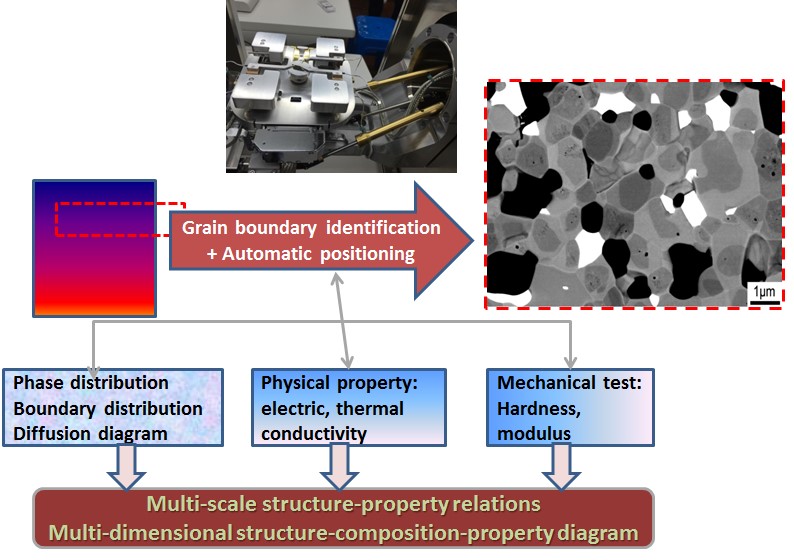

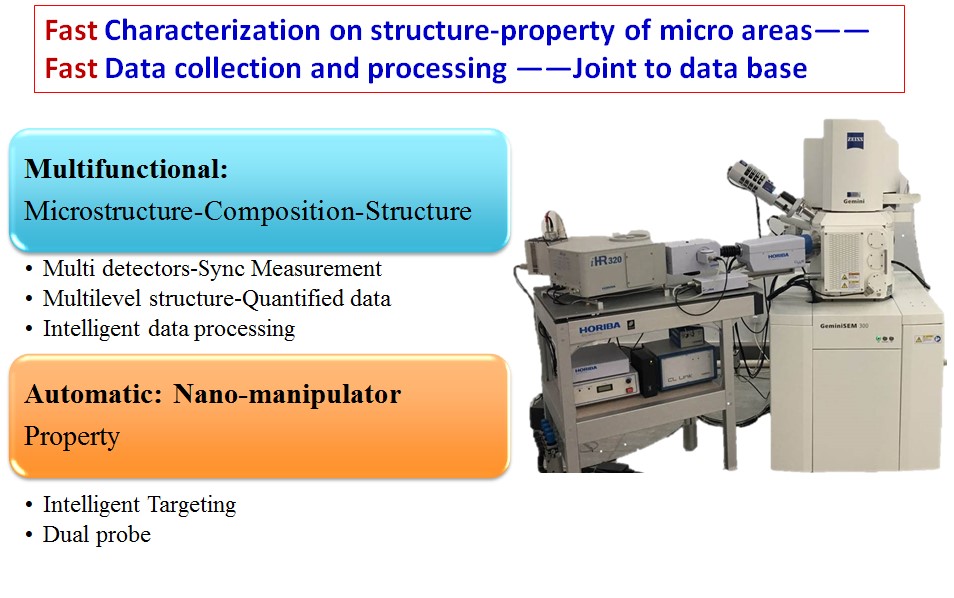

7. Automatic, Integrated SEM Platform

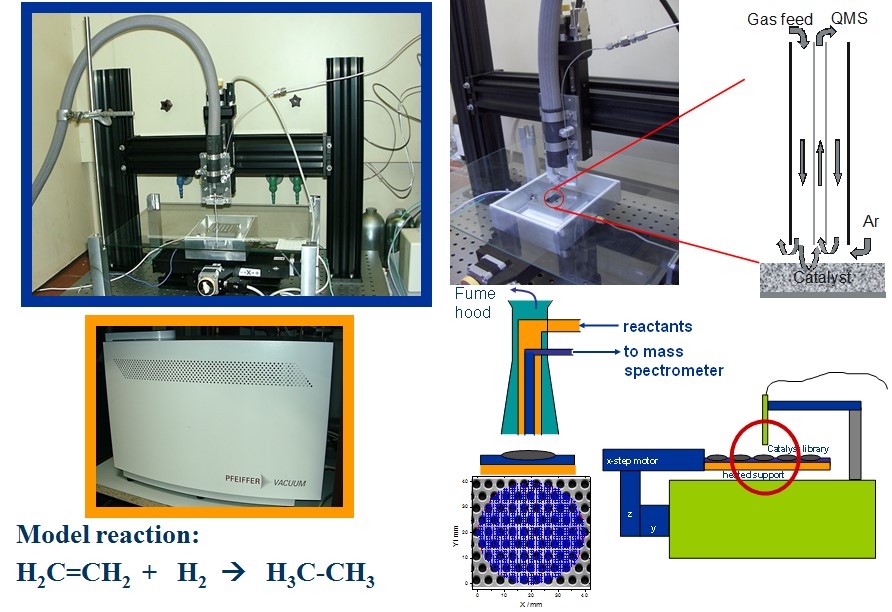

8. Spatially scanning mass spectrometry for catalyst evaluation

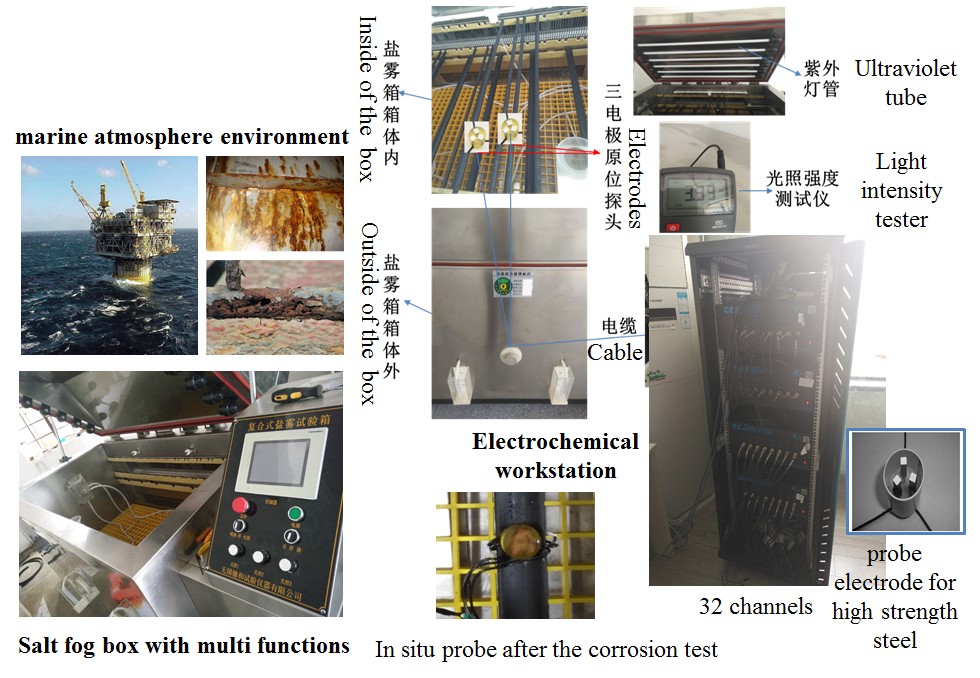

9. Multi-factor, Multi-sample Corrosion Test Device (Temperature, humidity, salt, light…)

10. Interactive microstructure characterization

By integrating electron and mechanical probes in SEM platform, continuous or arrayed samples, their microstructural and local properties could be interactively correlated across the macro-micro-nano scales.